Any electrical installation can be a dangerous task and requires proper knowledge. Wiring a 220V for a welder is such a process, but if you know how to go about it, it is not impossible either. Typically, a qualified electrician is required to perform this job, but if you will feel confident enough about handling electrical equipment, then this article is for you.

A 220V welder is suitable for heavy-duty applications, and you’ll need to wire an outdoor welding outlet for your household welding tasks. In addition, this type of welder draws a huge amount of current, thus, it needs substantial wiring.

You’ll also need to have knowledge of the correct size of the circuit breaker and the amount of amperage before you operate your welder with proper safety. For a 220V welder, you’ll need to go with a 50 amp breaker and a 3 prong heavy duty outlet.

The wire gauge also needs to accommodate the specific current required by your welder. For example, in our case, the 50 amps circuit breaker will need a 6-gauge wire. So, without further ado, let’s proceed to the step by step guide on how to hook up a 220 outlet for a welder.

Wiring a 220 outlet for a welder: Step by step guide

For this project you’ll need;

- A 6 AVG wire

- Flush mount 2 gang box

- 50 amp two-pole breaker

- Non-corrosive adhesive

- Outlet cover

- Cable ripper and wire stripper

Step 1

Before anything else, turn off the circuit breaker and ensure to lock the handle off. The main power to the breaker box should be dead and don’t touch anything, especially metal parts before closing the switch.

Step 2

Once the circuit breaker is off, now you can proceed to gain access to the breakers by removing the metal cover. By now, we believe you have already acquired a breaker, an outlet (flush mount 2 gang box), and a length of electric wire from your local electrical supply store.

Ensure to get high-quality materials for this project to prevent electrocution hazard and damage to your equipment. For instance, an overloaded circuit is a clear hazard, so if you are not sure of what to get, you should ask for assistance. Thus, ensure that the breaker is rated at or above the amperage requirement for your specific welder, and also the right gauge wire and outlet to match the plug of your welder.

Step 3

The next step is to identify the make of your breaker box to determine if it can accommodate a two-pole breaker as required.

Click to check the best 50 amp two-pole breaker

Step 4

Place your 50 amp two-pole breaker inside the breaker box in the two spaces provided.

Step 5

Determine the distance from your circuit breaker to where you want to install the outlet. Mark a hole on the wall where you want to wire the 220V outlet, then attach flush mount 2 gang box and screw it place. Choose the shortest route, and this may require you to go through walls or the floor. Also, it may require you to take several measurements depending on the obstacles between the circuit breaker box and the outlet or the layout of your space.

Step 6

It is now time to do the wiring. You’ll need to have a minimum of about 6 inches of wire inside your 2 gang box. Use a cable ripper to pull out the plastic sheath off the wire. Some sheathing should remain exposed in your receptacle box.

Step 7

Use the same cable ripper to pull out about 12 inches of the plastic sheath of the wire to be used inside the circuit breaker box. Just like the 2 gang box, you should also have some plastic sheath remain exposed in your circuit breaker box.

Step 8

At this point, you’ll now need to connect the wires. First, you’ll need to work on the work on the wires inside your 2 gang box. Ideally, for this project, you’ll have black, red, and bare wires. Both the black and red are hot while the bare one is the ground. Some connections may have a white one, but it is neutral, so it is not necessary.

Step 9

Now use your wire stripper to strip off 1 inch of the sheath at the tip of the wire and be careful not to strip more than is recommended. Apply some non-corrosive material at the tip of your wires to prevent the connection from corroding.

Step 10

Take your wires (black, red, and bare) and hook them against their respective screws. The red and black ones should be hooked to the two-prong terminal while the bare wire should be attached to the ground terminal. You can now put the cover on and ensure to fix it properly. That’s it with the 2 gang box.

Step 11

The next step is to connect all the three wires with the circuit breaker. Again the wires need to be stripped off and wrapped with non-corrosive at the end to establish a secure connection. You can use the breaker manual to help you know the correct terminals to connect your wires. If you have the white wire, you will need to seal and keep it securely inside the 2 gang box.

Step 12

Double-check everything to ensure that your connections are routed properly and that the wires are installed securely. If you’re satisfied with the connections, cover your circuit breaker box and plug in your welder at the outlet. You can now turn on the main power supply followed by the 50 amp breaker, and at this point, your machine is now ready to weld.

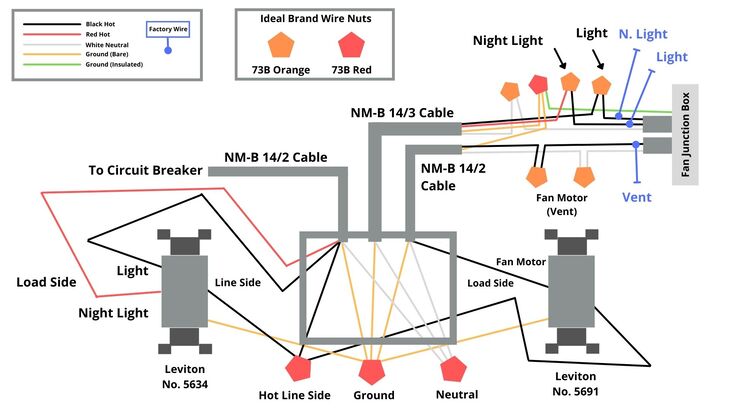

220V Welder Plug Wiring Diagram

Final Remarks

We hope that we have tried to explain the process in simple terms as possible, and with proper safety precautions, you should be able to run a 220 outlet for a welder with just a few tools. Keep in mind that you need to get quality materials for this project, but if you are not comfortable enough, it is always a good idea to hire a licensed electrician. Safe welding!